|

ANALYSING AND SYNTHESISING MULTIFOCUSED MANUFACTURING STRATEGIES BY ANALYTICAL HIERARCHY PROCESS ANALÝZA A SYNTÉZA VIACHÅADISKOVÝCH VÝROBNÝCH STRATÉGIÍ ANALYTICkÝM HIERARCHICKÝM POSTUPOM PROCESU Josu Takala

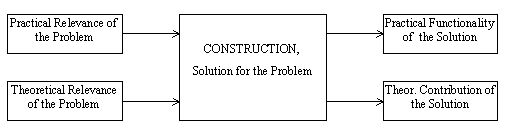

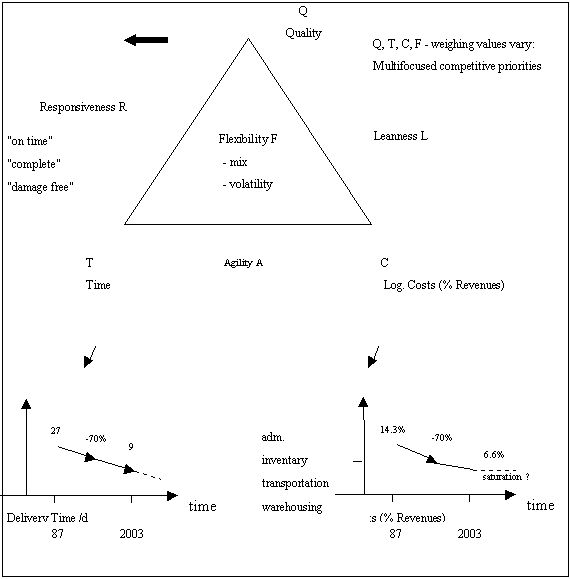

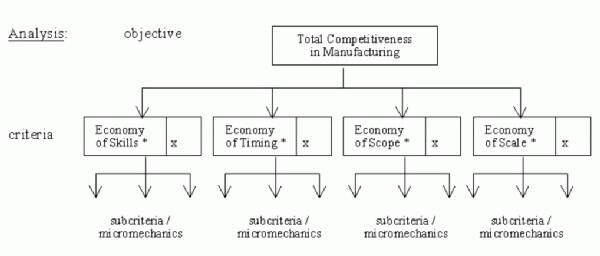

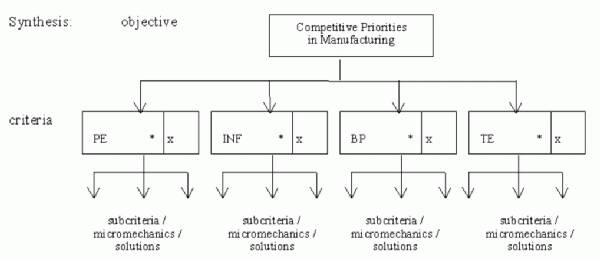

The significance of technology is all the time growing with the global and dynamic changes such as trade liberalization, networking, knowledge and service economies, environmental control and many emerging technologies. Therefore, from the 1970’s to the 1990’s, the competitive strategies in manufacturing have changed dramatically from focused to multifocused priorities. /17/, /5/, /12/, /13/ and /16/. The companies can and must have several high performances simultaneously, e.g. quality, time, cost and flexibility competitivenesses. The researchers are keenly searching methods how to measure and develop multifocused manufacturing strategies, and the results, e.g. competence, time or flexibility based strategies, are promising. However, these strategies have not yet been tested empirically widely enough. This study aims at analysing, synthesising and implementing multifocused competitive strategies empirically by using descriptive and constructive case research approach. The research problem and questions are hermeneutic. We are interested in what are the reasons of the deviation in the expert’s opinions, and how they affect the successful implementation of manufacturing strategies. The work uses as the basis over 100 participative and empirical case studies carried out from 1992 to 1996. Quite many cases - typically from small and medium sized organizations striving for higher competitiveness - are from the reindustrialization research programmes carried out in Finland and especially in the County of Vaasa. Using this case research as the basis a new method for the analysis and synthesis of multifocused manufacturing strategies has been developed and preliminarily verified empirically by 10 new cases between 1996-2000. The epistemology of this quite explorative study bases therefore firmly on empiria, and the ontology on participative or action research carried out by study groups of more than 2 researchers in each case. These teams consist of at least 1 separate member from case to case, and participants from the case company and from the university as well. The research approach is mainly constructive and utilises the philosophy of building new theory - that is more detailed and profiled construction compared to the basic solution for the research problem presented – from case study research. /1/, /18/. Figure 1 shows the constructive research approach in business science. /3/.  Fig. 1 Constructive Research Approach in Business Science. /3/ From the 1970’s to the 1990’s, the competitive strategies in manufacturing have changed dramatically from focused (the previous paradigm) to multifocused (the new paradigm) priorities. /12/, /13/, /16/. The research questions presented with the paradigm shift in manufacturing strategies show the practical and theoretical relevance of the construction (Figure 1) and at the same time the research gap. The companies can and must have several high performances simultaneously, e.g. quality, time, cost and flexibility competitiveness. /2/, /6/. The researchers are keenly searching methods how to measure and develop multifocused manufacturing strategies, and the results, e.g. competence, time or flexibility based strategies, are promising. One very challenging example of multifocused manufacturing strategies waiting for empirical work is Responsiveness, Agility and Leanness (RAL) Concept shown in Figure 2. /7/. RAL has basically been created for logistics but it is obviously relevant for manufacturing strategies as well. The author has modified RAL Concept by taking into the discussion the (product and production) flexibility concept. Logistics/ Benchmark; RAL-Concept R= responsiveness; "speed by which the system satisfies unanticipated requirements" A= agility; "speed by which the system adapts to the optimal cost structure" L= leanness; "minimizes waste in all resources and activities"  Fig. 2: RAL Concept. /6/. Modified by the author by adding the flexibility concept. à AVAILABILITY is the key issue! Building new theories from case study research works well as the methodological basis for the study. /1/, /18/. So, we follow this strategy when searching for a more detailed and profiled construction basing on the empiria gathered. /8/. Our basic solution (construction) for the research problem is presented in Figure 3. /16/, /4/.   Fig. 3 Analytical Hierarchy Process based basic constructions for analysing and synthesising manufacturing strategies by competitive priorities. * = competitive priorities, x = weighing values (sum =1). /10/.

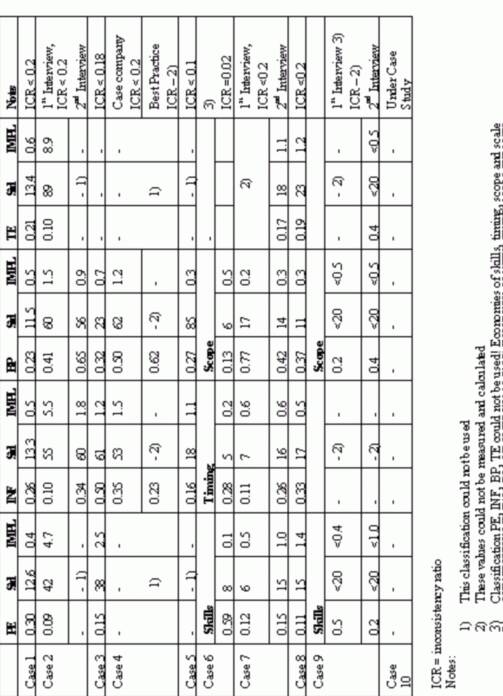

The new method utilises pairwise comparison with analytical hierarchy process (AHP) by interviewing - utilising altogether a group of over 10 researchers (typically at least 1 researcher/case) - the experts of the manufacturing strategies and tactics within the whole supply chain. The interviews have been carried out by semistructured questionnaires with few open questions. The research methods include a literature survey, descriptive conceptual analysis, analysing mainly qualitative (including texts and talks as well, /11/) but to some extent also quantitative data, classification by simple statistics, and finally, constructive synthesis (including weak market tests (WMT) and pilots, /3/) for implementing the strategies. The typically large case companies - from high tech and knowledge businesses except cases 5 (medium sized), 7, 9 (food industries) and 10 (small business with different technology levels) - represent high performance organizations (HPOs, /16/) in growing markets (in cases 7 and 9 decreasing) with not increasing prices. Almost all the case companies make business to customer orders (except cases 4 and 9 where make-to-stock business is combined with make-to-order business) with increasing usage of inbound and/or outbound strategic networks. The case applications are involved with customers (cases 1, 5, 6 and 7), suppliers (cases 2 and 4), internal business processes and information systems (cases 3, 7 and 8) or whole the business process (cases 9 and 10). In conclusion, case company 9 is – for comparison purposes (!), quite different compared to all the other case companies. It represents food industries obliged recently to free competition in the markets, and for that reason it suffers from contradictions in the strategy just today. These contradictions should cause disturbances in the implementation process of manufacturing strategies compared to all the other cases. All the case studies have been carried out by using both the basic constructions for the analysis and synthesis depicted in Fig. 3 starting from the analysis of economies (of skills,…, scale), and going on with synthesis, weak market tests/pilots and implementation microstructures and results of the competitive priorities in the manufacturing strategies (PE,…, TE). The number of the interviewed high competence experts has been quite low (typically 10 except about 30 in case 6) but quite representative to understand the high business dynamics in the whole supply chain. The data gathered - typically from quite a well limited and described application problem (/8/, improving the required careful documentation of the case, /14/ and /15/) - has typically been mainly qualitative in nature. Competitive priorities should be openly considered in the design of a manufacturing performance measurement system, directed at supervising the correct implementation of the manufacturing strategy at all the levels of the manufacturing organizational structure. The analytical hierarchy process (AHP) is a method for measuring and comparing the multifeature financial and non-financial performance criteria. /9/. How to apply AHP for this kind of situations has been described in the case publications. /8/. The important features, the inconsistency ratio, and the axioms; reciprocal condition, homogeneity, dependence and expectation are the basis for AHP applications. /6/. This multi-case study, from 1996 up to 2000, follows the philosophy developed by K.Eisenhardt (/1/) and applied in quite a similar way for more detailed and profiled constructions for the implementation of manufacturing strategies by Wilson and Vlosky (/18/) in partnering relationships. The details and profiles as the contributions to the basic construction (Fig. 3) have been searched from the longitudinal case studies - lasting typically from half a year to two years each. This has been done by analysing the deviations of the expert opinions on competitive priorities and by finding out the reasons for the deviations and especially the affects the deviations have in the implementation process of manufacturing strategies. The success of weak market test, enabling and hindering microstructures, pilots and achieved financial and non-financial results within one year from the beginning of the case development task. To increase the sensitivity of the deviation in competitive priorities when considering the implementation processes of manufacturing strategies the standard deviation has been developed into implementation index (IMPL) by dividing the standard deviation by the value of corresponding competitive priority in order to improve the possibility to compare different cases with each other. In addition to these measured and calculated competitive priority, standard deviation and implementation index values, quite a deep textual description on the different stages of the implementation procedure of manufacturing strategies in the case companies has been introduced. The validity and reliability criteria of the case studies can be utilized for this concluding research especially thanks to the careful documentation used in the case companies by the study teams. /8/, /4/, /6/, /14/ and /15/. The economies of skills, timing and/or scope have typically the highest priorities compared to economies of scale, except in cases 2, 4, 8 and 9 where also economies of scale is of high priority (and timing the lowest priority!), and in case 6 where timing and scale have lower priorities than the other economies, and in case 10 where the economies are rather unknown! /16/ and /8/. Table 1 presents the basic numerical results achieved from the case interviews. Table 1: AHP Results; Competitive Priorities (PE, INF, BP, TE), Standard Deviations (Std %) and Implementations Indexes (IMPL= Std/competitive priority)

From Table 1 we can find out that there are very extensive differences between the cases. Therefore, the competitive priorities with their standard deviations and implementation indexes should be more carefully considered. This textual description should also contribute to the basic constructions (Fig. 3) with more details and profiles on microstructures, weak market tests (WMT), pilots etc. This description is presented case by case and hopefully gives understanding to the implementation differences. Case 1: The competitive priorities are quite even. PE is the biggest caused by the fact that the strategic business view is very much based on the economies of skills. This focuses IMPL on PE to be the lowest (best) one. All the IMPLs are small. WMT was also successful. These facts forecast good results in the implementation process. /4/. Case 2: The competitive priority BP with IMPL related to it are the best ones caused by the fact that the strategic view is decentralized on economies of skills, scope and scale (even a little bit on timing, too). Although the IMPL focus related to BP was rather bad (all IMPLs were big!), WMT and pilots were successful thanks to the limited scope of the development activity. The results have been extremely nice. The planned improvements of the delivery promptness of all the suppliers have been introduced widely in the case company! /8, Mäkelä, P./. Case 3: The competitive priority INF with IMPL focus on BP are the best ones caused by the fact that the strategic view is based mainly on skills (competences) but on the other economies, too. Although all IMPLs are rather bad, WMT was successful. However, the forecasts on the future results related to the internal information systems of the case company are not necessarily good! /8, Haukilehto, S./. Case 4: The competitive priority BP with IMPL focus on BP are the best ones caused by the fact that the business view is based on all the economies quite evenly. All IMPLs were rather bad and WMT was not either successful! The only thing that gives hope for good future results is that the implementation procedure for the software supplier BP was quite similar in the best practice company. /8, Niemi, P./. Case 5: The competitive priority BP with IMPL focus on BP are the best ones caused by the fact that the business view is based on all the economies quite evenly. However, all IMPLs were quite nice. WMT has not yet been carried out. The thing that also gives hope for good future results is that the scope of the implementation procedure, for the improvement of the delivery promptness to the main customers, could be limited quite well. Anyhow, the results will be good only if the main customers will be committed enough to the development action with the case company! /8, Järvensivu, P./. Case 6: This case is quite different compared to all the other cases, and in many ways. The economies of skills, scope, scale and timing was studied with a high number of interviews during almost two-year case work. However, the scope of the application was well concentrated on customer satisfaction procedures. The economies of skills and IMPL focus related also to it were the best ones. All IMPLs were nice. WMT and pilots have also been successful. The implementation results of the new customer satisfaction procedures have been extremely good and extensive in the case company. /6/ and /8, Luoma, S./. Case 7: The competitive priority BP with IMPL focus on BP are the best ones caused by the fact that the business view is based on all the economies quite evenly. All other IMPLs were rather bad. WMT has not yet been carried out. However, a very limited but well concentrated pilot implementation related to the internal product data management systems has been carried out. Another thing that gives hope for good future results is that the scope of the implementation procedure, for the improvement of the delivery promptness to the main customers, could be limited quite well. Anyhow, the results will be good only if the main customers (and suppliers as well) will be committed enough to the development action with the case company! /8, Leppinen, P./. Case 8: The competitive priority BP with IMPL focus on BP are the best ones caused by the fact that the business view is based on all the economies quite evenly (except on timing which is of the lowest priority). All other IMPLs were rather bad. WMT was successful! The implementation forecast with results is in this public university internal process good especially because competitive priority PE has not indicated to be any problem. /8, Järvensivu, P. & Penttilä, J./. Case 9: This case is quite different compared to all the other cases, and in many ways just for comparison purposes! The economies of skills and scope were studied in the first interview, and the competitive priorities in the second interview. The scope of the application was well concentrated on manufacturing maintenance development procedures. The economies of skills and scope are dominating. The competitive priorities BP and TE, and IMPLs focused also on them were the best ones. These IMPLs were nice, and even WMT with some pilots (related to BP and PE) have also been successful. However, we are not expecting any good results in the near future because of the contradicting strategic view in the totally new situation in the free markets with rather bad problems in the manufacturing technology not yet fitting so well to the higher requirements of product variety. The bad forecast on the future results in the implementation process of the manufacturing strategies can also be concluded from the two competing competitive priorities and IMPLs - not just one which has been the situation in all the other cases! /8, Takala, J./. Case 10: This case is mainly concentrated on small business (or on larger companies with their suppliers) by using (technology) benchmarking as a tool to develop manufacturing strategies by using competitive priorities. About 30 case companies are under research utilizing mainly AHP method during 1999-2000. The purpose is to extend the results of the early work to the small business as well. The theoretical relevance of the constructions on the multifocused manufacturing strategies proposed (Fig. 3) bases on the multifocused competitive priorities in manufacturing that have been quite extensively published. These priorities are different from industry to industry, from company to company and from time to time. /13/ and /16/. The practical relevance of the more detailed and profiled constructions, basing on the empirical case work, on the successful implementation processes of multifocused manufacturing strategies bases on the implementation procedure with its different stages improving the understanding about the research problem stated: what are the reasons and effects of the differences in experts’ opinions? The validity, reliability and generalizability of this research has been improved by multiple and longitudinal case studies (lasting from half a year up to 2 years per case). Besides, the same method (AHP), separate development teams in each case (e.g. altogether over 10 university researchers increasing the objectivity), versatile study methods with triangulated information sources and careful documentation of the cases (/8/, /14/ and /15/) have also been utilized. The inconsistency ratios, standard deviations and implementation indexes, which make possible the comparisons between the cases, have not necessarily been in all the cases on an acceptable level. This is because we have tried to create new and dynamic constructions that could be utilized in a very strict time frame with a small number of experts’ opinions in dynamic markets. It has been said that case studies should not be generalized at all! However, we could at least try to do it basing on the cases carried out. We have noticed that the strategic business view does put the basis for putting the operational focus on the right manufacturing strategies. If the view is clear and stable enough focusing operations will be easy with nice competitive priorities and implementation indexes. If the view is unclear or unstable at this moment focusing operations for new manufacturing strategies will fail even if the operations would be very concrete (see e.g. case 9). The weak market test with the consideration of enabling / hindering micromechanisms verifies the possibility for successful implementation process. The case study also shows that if the implementation index is below 1 for just one focused competitive priority, the forecast will be very good for nice results within the introduction period of just one-year. Generally, it might be said that the implementation index provides us with a new measurement between strategic view and operational focus thanks to its capability to measure sensitively common opinions and commitments during the implementation processes of manufacturing strategies. How to focus the further research? It is quite obvious that follow-up work lasting at least one year in the case companies will provide us with better evidence on the effects (benefits, disadvantages, experiences and results) caused by the new profiled constructions. It could also be beneficial to make the cases more homogenous related to industrial areas and other parameters, if possible, and to make similar study to verify the construction as a hypothesis for statistical quantitative analysis providing us with positivistic models for manufacturing strategies. Anyhow, this research work will be continued with case 10 in small business where new challenges in manufacturing strategies will be found out because of the holistic nature of business. REFERENCES Eisenhardt, K. M (1989). Building Theories from Case Study Research, Academy of Management Review, vol. 14, no. 4, pp. 532-550. Gervin, D. (1993). Manufacturing Flexibility: A Strategic Perspective, Management Science. 39(4). The Institute of Management Science. pp. 395-410. Kasanen, Lukka & Siitonen (1991). Constructive Research Approach in Business Science. Liiketaloudellinen Aikakauskirja 40:3, 306 p. Kemppainen, T. & Takala, J. (1999). Using global Business Integration Framework in Logistics Process Standardization. ICPR’99 (International Conference on Production Research), Limerick, Ireland, 4 p. Kim, J. S. & Arnold, P. (1996). Operationalizing manufacturing strategy – An exploratory study of constructs and linkage. International Journal of Operation & Product Management 16: 12. pp. 45-73. Luoma, S. & Takala, J. (1999). Analytical Hierarchy Process on Customer Driven Project Development. ICPR’99 (International Conference on Production Research), Limerick, Ireland, 4 p. Pfohl, H-C. (1999). Notes on the Discussions between Pfohl and Takala 13 th Nov 1999 in Turku, Finland on RAL Concept. European Logistics Association ( www.elalog.org), 4 p.Pro Graduation Theses and Working Reports: Kemppainen, T. (1998), Mäkelä, P. (1999, in Finnish), Haukilehto, S. (2000), Niemi, P.(2000), Järvensivu, P. (2000, in Finnish), Luoma, S.(2000, in Finnish), Leppinen, P. (unpublished by now), Penttilä, J. & Järvensivu, P.(2000, in Finnish), Takala, J. (1997 and 1999, in Finnish). University of Vaasa, Department of Information Technology and Production Economics, Finland. (unpublished). Rangone, A. (1996). An analytical hierarchy process framework for comparing the overall performance of manufacturing departments. International Journal of Operation & Product Management 16:8, pp.104-119. Saaty, T.L.(1980). The Analytical Hierarchy Process: Planning, Priority Setting, Resource Allocation. U.S.A, McGraw-Hill Inc., 287 p. Silverman, D. (1993). Interpreting Qualitative Data. Methods for Analysing Talk, Text and Interaction. London. SAGE Publications. 225 p. Skinner, W. (1974). The focused factory. Harvard Business Review. 52(3). pp. 113-122. Spina, G. & Andrea, B. & Cagliano, R. & Draaijer, D. &Boer, H. (1998). Strategically flexible production: the multi-focused manufacturing paradigm. International Journal of Operations & Production Management. 16(11). MCB University Press. pp. 20-41. Sykes, W. (1990). Validity and reliability in qualitative market research: a review of the literature. Journal of the Market Research Society. 30 (3). pp. 289-328. Sykes, W. (1991). Taking stock: issues from the literature on validity and reliability in qualitative research. Journal of the Market Research Society. 33 (1). pp. 3-12. Takala, J. (1997). Developing Technological Competitiveness of High Performance Organizations basing on the Relationship between Technology Management and Total Quality Management. ICPQR’99 (The 6th International Conference on Productivity and Quality Research), Houston, U.S.A, 15 p. Wheelwright, S. C. (1978). Reflecting Corporate Strategy in Manufacturing Decisions. Business Horizons. February. pp. 57-66. Wilson, E. J. &Vlosky, R. P. (1997). Partnering Relationship Activities: Building Theory from Case Study Research. Journal of Business Research 39. Elsevier Science Inc. pp. 59-70. ABOUT THE AUTHOR / O AUTOROVI Josu Takala, Dr. Tech., professor in Production Economics, head of the dept. Prof. Josu Takala University of Vaasa/Production Economics P.O. BOX 700, FIN-65101 Vaasa, Finland Tel. +358-6-3248111, +358-400-564068 Fax +358-6-3248467 Email: josu.takala@uwasa.fi

|